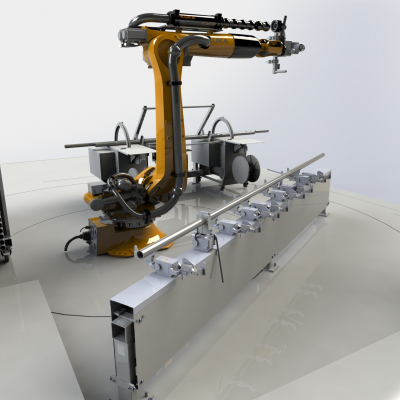

wire protection pipe cell

Fully automatic production cell for the manufactoring of plastic pipes

The fully automatic Wire protection pipe cell – WPPC – manufactures PET pipes for track crossings. The orders are triggered via a direct SAP connection and processed depending on their prioritization. The main tasks are done by a 6-axis robot, supported by different workstations.

Features

- Scanning of the raw material for detection “upper tube”

- Automatic “pick and place” of the tube from the storage location to the clamping station

- Milling and deburring of bores and grooves

- Quality control by measuring last processing

- Stacking of the tubes on the binding station

- Binding to tube packages

- Labeling

- Unloading onto transport trolleys

- Control of successful discharge

- Start new job

Components

- Industrial robot KUKA KR 120kg R3100mm

- Water-cooled electrospindle with HSK tool holder

- Pneumatic gripper

- Swarf extraction

- Pipe scanner

- Raw material storage spread over two wagons

- Clamping station with pneumatic radial grippers

- Binding station

- Label printer with applicator

- Enclosure with automatic sliding gate